The production-linked incentive scheme has made notable strides in realising India’s ambitions of becoming a global electronics manufacturing powerhouse. With an outlay of Rs 22,919 crore, the PLI initiative has helped boost exports and reduce import dependence—most dramatically in the smartphone sector. A decade ago, mobile phones were India’s 67th-largest export. Today, they rank second.

Since the scheme’s formal launch in April 2020 and full implementation a year later, electronics exports have nearly doubled—from Rs 233.9 billion in FY21 to Rs 473.4 billion in FY22. With this momentum, the government is planning a new round of global roadshows, in partnership with industry body ICEA, to woo international investors and pitch India as a hub for electronic component manufacturing. Targeted outreach in South Korea, Japan, Taiwan, and the US is intended to drive interest as the scheme nears its deadline in three months, with expectations of attracting $6.94 billion in fresh investments and generating $53.3 billion in revenue over six years.

READ | Spain-Portugal blackout exposes Europe’s green energy agenda

But behind this progress lies a more complex reality. India has set an ambitious $500 billion electronics manufacturing target by 2030. While marquee names such as Murata, TDK, and Dixon Technologies have shown interest, India still accounts for just 2% of global electronics production—dwarfed by China’s commanding 60%. For all the fanfare, India remains a marginal player in the global value chain.

Structural headwinds

India’s struggle to scale up its electronics industry is not from lack of ambition, but because of deep-rooted structural deficiencies. For global precision-driven manufacturers, infrastructure remains a major stumbling block. Unreliable electricity, logistical delays, and inadequate port facilities inflate costs and deter investors. Unlike Taiwan’s Hsinchu Science Park or South Korea’s Incheon hub—both models of integrated infrastructure and just-in-time logistics—India’s industrial parks remain fragmented and under-equipped.

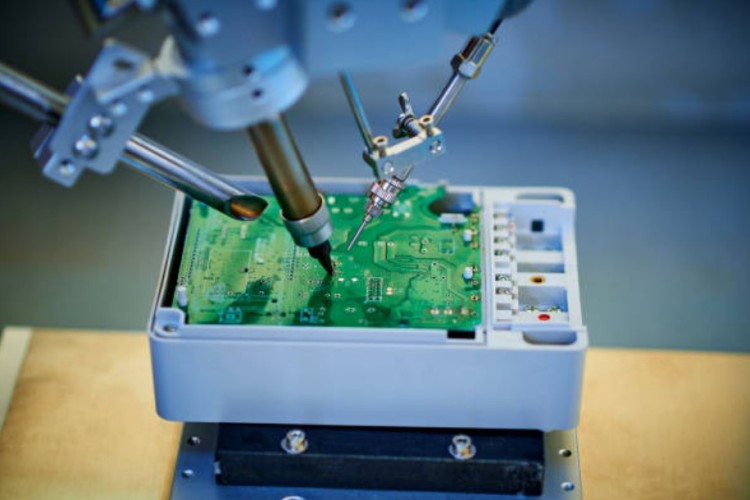

Supply chain gaps also persist. Key inputs like printed circuit boards (PCBs) and lithium-ion cells are in short domestic supply, driving up costs and limiting India’s competitiveness. While the PLI scheme tries to plug these gaps, achieving economies of scale in such a capital-intensive industry remains a steep climb.

A trust deficit

A recurring concern among investors is India’s policy unpredictability. Despite its grand announcements, the government’s frequent course corrections undermine confidence. The India Semiconductor Mission, launched in 2021 with Rs 76,000 crore in incentives, promised to be a game-changer. But the experience of early applicants paints a cautionary tale.

By 2022, firms such as Vedanta-Foxconn and IGSS Ventures had submitted proposals for semiconductor fabrication under the PLI scheme. However, shifting eligibility norms, bureaucratic delays, and opaque approval processes began to derail the initiative. Vedanta’s $19 billion plan, for instance, ran into trouble over concerns regarding its technology partner. In 2024, the government further revised the scheme to favour “mature nodes,” effectively disqualifying some applicants already committed to more advanced nodes.

These flip-flops have pushed some investors to scale back plans or divert them to more stable destinations like Vietnam and Malaysia. Even prominent players like Zoho have expressed doubts over return on investment given the shifting goalposts. As The Financial Express reported in October 2024, the sector’s halting progress raises serious questions about India’s ability to match the precision and policy stability of East Asian giants.

Talent gaps and skill deficits

Another critical barrier lies in human capital. Electronics manufacturing requires a highly skilled workforce trained in next-generation technologies. Yet India’s technical education system is lagging. The number of qualified engineers in high-end electronics and chip design is a fraction of what China or Taiwan produce annually.

India’s electronics exports in FY24 were pegged at $20 billion—a far cry from China’s staggering $800 billion. The comparison underlines the gap India must bridge, not just in infrastructure or policy but in talent and innovation ecosystems.

Learning from the leaders

There are valuable lessons in the rise of China, Taiwan, South Korea, and Vietnam. China’s dominance in manufacturing is built on decades of state-led infrastructure investment and a hybrid political model that centralises authority while decentralising implementation. This enabled swift and large-scale reforms—an approach India is only beginning to emulate.

Take Shenzhen. Today, it functions as a seamless one-stop hub where firms like Foxconn can source components, labour, and logistics within hours. India’s dispersed and often poorly managed industrial zones can’t yet offer this level of efficiency. Moreover, unlike Japan and South Korea, India lacks large vertically integrated conglomerates. Its electronics sector is dominated by small and medium enterprises with limited capacity to scale or compete globally.

Opportunity in electronics manufacturing

The PLI scheme deserves credit for catalysing a conversation around manufacturing-led growth. And the timing of India’s outreach coincides with a global reordering of supply chains, driven in part by the US-China trade tensions. This offers India a window to attract companies looking to diversify out of China.

But that opportunity comes with a caveat. Many of these firms still depend on Chinese suppliers for components. If India mishandles this pivot—by being overly nationalistic or imposing unnecessary restrictions—it risks alienating key parts of the supply chain.

For India to truly break into the global top tier of electronics manufacturing, it must prioritise long-term consistency over short-term optics. Infrastructure must be upgraded, policies must be predictable, and workforce skills must be radically improved. The $500 billion dream is not out of reach—but any misstep now could turn ambition into illusion.